Injection – specialist in plastic and rubber injection

Specialist in the injection of plastic or rubber in single or bi-material mode, as well as metal overmoulding, we keep your most ambitious promises.

Implement your ideas and exceed your expectations

Our high level of vertical integration allows us to implement your specifications quickly. In addition to being rigorous and having real integrity, our teams have developed their capacity to suggest solutions and manage projects. They work with you in complete transparency, and keep all your information confidential, so you can attain your objectives.

A wide array of materials

In addition to standard materials (ABS, PS, PP, PC, etc.), we inject a wide variety of technical materials that lend themselves to the precision required by customers while also meeting environmental constraints: PPS, PA, TPU-TPE, PBT, POM, PPA, EMAA/EAA, ETFE, PMMA, PEEK, SBC, and the vulcanized elastomers HNBR, FKM.

We are connected to the materials database of the European Pole for Plastics, based 40 km from our French factory, and are actively involved in the identification of new bio-sourced, biodegradable, or easily recycled materials. We are able to propose you alternative and innovating solutions.

Versatile, high-performance equipment

• Our machines are so versatile that we can inject parts of all sizes, from 1 to 650 mm, in small or large series. In addition to traditional injection techniques, we are also masters of overmoulding, bi-material injection, vulcanisation, and machining of plastics.

• We have 20 production machines: plastic injection presses with clamping forces ranging from 15 to 250 tons, including modular, bi-material machines to inject complex parts, and rubber presses with 140 tons of clamping force.

• Vulcanisation and cryogenic deburring chambers for elastomer, rubber and VMQ silicone rubber parts for providing impeccable finishing.

• High-performance metrology instruments in rooms with controlled atmosphere for the control of part size.

• Surface treatment in clean rooms.

Our Markets

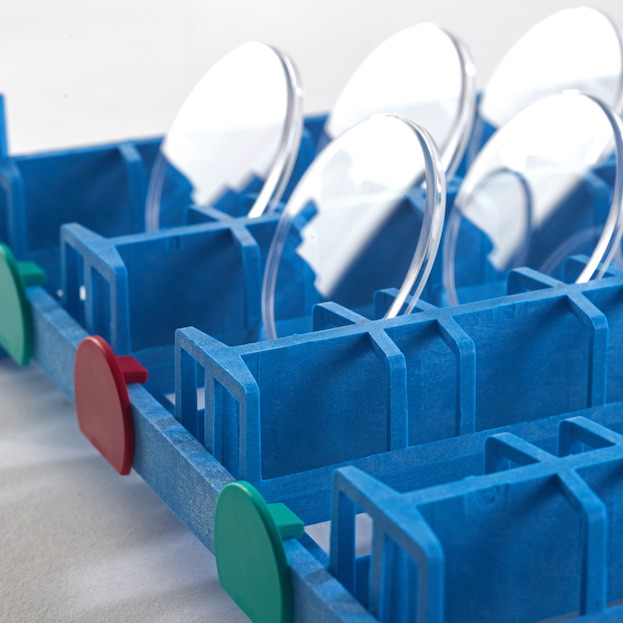

INDUSTRY

Inter-operation packaging: wide range of baskets in different materials and support in rationalising your flows.